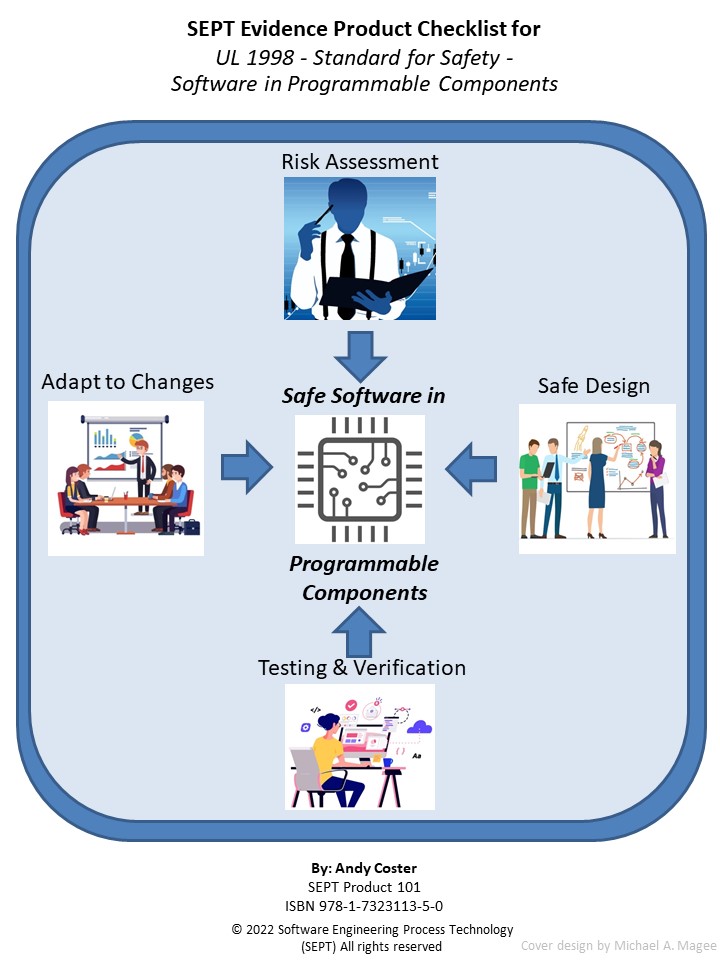

Evidence Product Checklist For UL 1998 Standard for Safety - Software in Programmable Components

Author: Andy Coster

Cover: Available

Customer Set for this product: Customers that produces products that have software in a programmable coma ponent that possible could cause bodily harm, such as Medical devise or solar power units.

Format: PDF (Click here for our easy-to-modify Word® formatted version)

ISBN numbers: ISBN 978-1-7323113-5-0

Language: English

Page count of document: 97

Provider: SEPT

Sample Pages: Available

Shipping: Available for download - Link will be provided in My ComplianceOnline section

The UL 1998 standard is focused on application-specific, non-networked software in a programmable component that is embedded in a product for which a failure may result in injury to persons. In addition, UL 1998 is a reference software standard intended to be used in conjunction with any product specific safety standards that address safety requirements for the identified programmable component and the product hardware. A software configuration of a microprocessor based programmable component typically includes the operating system or executive software, communication software, micro-controller, input/output hardware, and any generic software libraries, database management or user interface software.

Sections of the Checklist:

- Section 1. Foreword

- Section 2. Checklist of all required and suggested UL1998:2018 (Edition 3) artifacts, by clause.

- Sections 3-7. Individual checklists for each type of artifact (procedures, plans, records, documents and reviews)

- Section 8. About the author

About the UL 1998 SEPT Checklist

The purpose of the checklist is to define clearly all the artifacts (procedures, plans, records, documents, or reviews) that the underlying standard calls out. Furthermore, what constitutes physical evidence (Artifacts) to meet the guidance outlined in UL1998 is sometimes difficult to identify. To bridge this gap the author and SEPT experts have identified items of physical evidence called out in the standard based on their knowledge of the document and their experience in the standards field. Each item of physical evidence that was identified by these experts is listed in the checklist as an artifact (Procedure, plan, records, document, or reviews.). . Sometimes we call out an artifact that is not expressly identified but we think it should be included. If that occurs, we flag it with an * as suggested. There must be an accompanying record of some type when a review has been accomplished. This record would define the findings of the review and any corrective action to be taken. For the sake of brevity this checklist does not call out a separate record for each review. All procedures should be reviewed but the checklist does not call out a review for each procedure, unless the standard calls out the procedure to be reviewed. Where records are cited as artifacts, reviews of the records are not included, but we would expect a review to be held.

In total, there are 208 artifacts identified by SEPT in the checklist, of which 69 are required and 139 suggested.

General Principles of the Checklist for “UL1998 - Standard for Safety - Software in Programmable Components”

This checklist was prepared by analyzing each clause of the Standard for the key words that signify a:

- Procedure

- Plan

- Records

- Document

- Review

This checklist specifies evidence that is unique. After reviewing the completed document, the second review was conducted from a common sense “reasonable person” approach.

The information was transferred into checklist tables, based on the type of product or evidence. In total, there are 199 artifacts identified by SEPT in the checklist. To better understand this model a user of this product should understand SEPT definition of an auditor. An auditor can be your boss, an inside auditor or an outside auditor such as the FDA, DoD or a prime contractor for your product. The checklist will give the auditor and you a common reference point in the standard (Clause number) that becomes the index point for physical evidence. If a standard calls out physical evidence more than once, such as a “training plan” it is always index to the first clause that reference the training plan This method will allow you to organize your physical evidence in a systematic manner for presentation to the auditor. This simple checklist allows you to bring the document down to simple terms that a professional lay person can understand (policy, procedure, plans, records, documents, audits and reviews).The checklist will allow the organization to divide the compliance activity into manageable work packages such as procedures, plans, documents etc.

The checklist is available in PDF or word format. The latter format allows you to tailor the document to your business case or the media that your organization wants to use the checklist in such as excel web

Using the Checklist

When a company is planning to use UL1998 standard, the company should review the evidence checklist. If the company’s present process does not address an UL1998 standard product, then the following question should be asked: “Is the evidence product required for the type of business of the organization?” If, in the view of the organization, the evidence is not required, the rationale should be documented and inserted in the checklist and quality manual. This rationale should pass the “reasonable person” rule. If the evidence is required, plans should be prepared to address the missing item(s). page format or any other end product type in order to meet compliance with the standard in the most efficient way possible

Product Support

All reasonable questions concerning this checklist, or its use will be addressed by SEPT free of charge for 60 days from time of purchase, up to a maximum of 4 hours of consultation time.

It provides information on:

1. Risk Analysis

2. Process Definition

3. Qualification of Design, Implementation and Verification Tools

4. Software Design

5. Critical and Supervisory Section of Software

6. Measures to Address Microelectronic Hardware Failure Modes

7. Product Interface

8. User Interface

9. Software Analysis and Testing

10. Documentation

11. Off-the-Shelf (OTS) Software.

12. Software Changes and Document Control 14. Documentation

13. Identification

This product supports these Software Engineering processes

- Configuration Management

- Design

- Documentation

- Integration

- Life Cycle

- Maintenance And Operation

- Quality

- Safety

- Verification And Validation

Customers of this product:

- AMETEK

- BUERMOOS GMBH

- CONTRINEX SA

- Gen-Probe

- Hewlett-Packard

- Iradimed Corporation

- Marathon Engine Systems

- MicroPlanet

- Preferred-mfg.

- QUALMARK

- Royal Philips Electronics

- Simex

- W&H Dental Work

Note: “International Standards (ISO) define the best of practices for Medical Device and Software firms in producing a quality product. This checklist that SEPT produces will ensure that all of the best of practices are adhered to.”

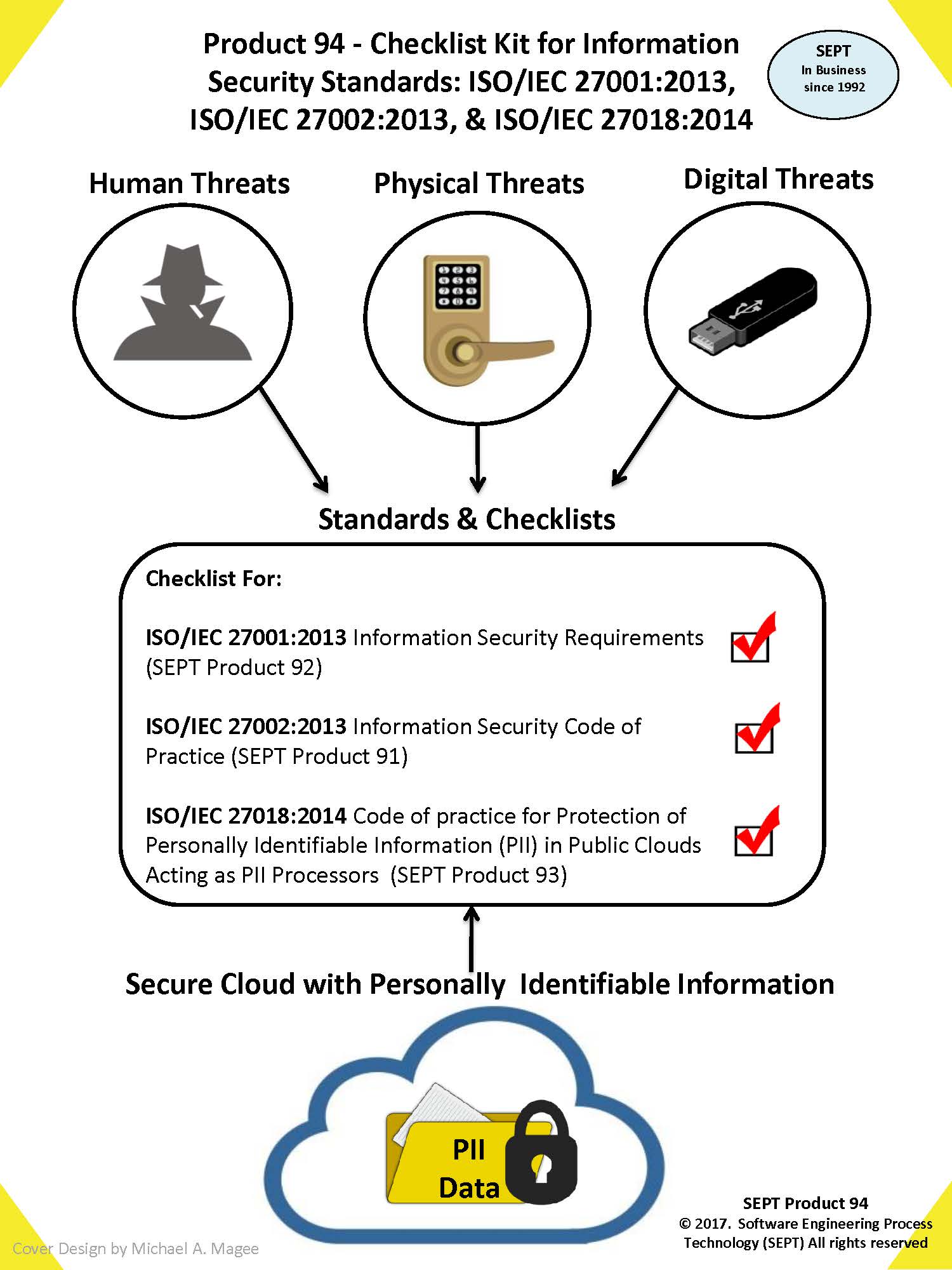

Customers Also Bought

- Electronic Signatures; Final Rule-FDA 21CFR Part 11

Price: $330 BUY NOW - Guidance for Industry, FDA Reviewers and Compliance on Off-the-Shelf Software Use in Medical Devices As amended by Guidance for Industry, FDA Reviewers and Compliance on Cyber security for Networked Medical Devices Containing Off-the Shelf (OTS) Software"

Price: $167 BUY NOW - ISO 13485:2016 “Medical Devices - Quality Management Systems- Requirements for Regulatory Purposes”

Price: $330 BUY NOW - Evidence Product Checklist For UL 1998 Standard for Safety - Software in Programmable Components

Price: $330 BUY NOW - IEC 62304:2015 ''Medical Device Software - Software Life Cycle Processes''

Price: $167 BUY NOW - Checklist for FDA, Guidance for the Content of Pre-market Submissions for Software Contained in Medical Devices.

Price: $167 BUY NOW